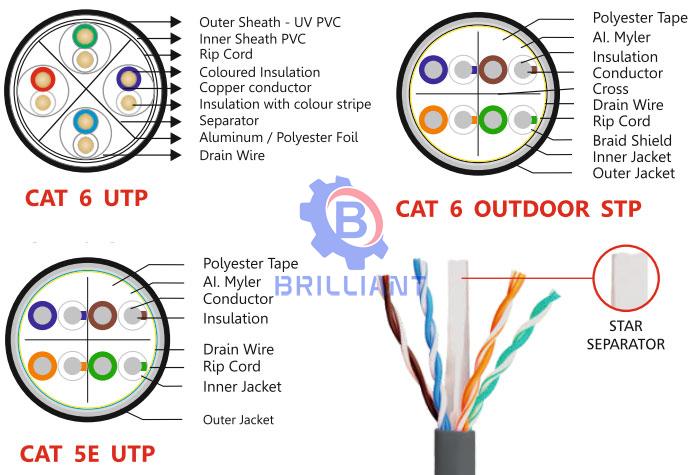

Lan Cable Structure for reference:

Lan Cable Production flow:

Step 1 50+35 Extruder to make pvc insulation and color injection

Step 2 500 Pair twisting machine to make pair twisted core wire

Step 3 800 Cantilever Single Twisting Machine to strand multi pairs and wrap with al foil

Step4 70 PVC Extruder to Make pvc insulation on the multi cores

Step 5 400 Coiling Machine to Pack the lan cable to coil

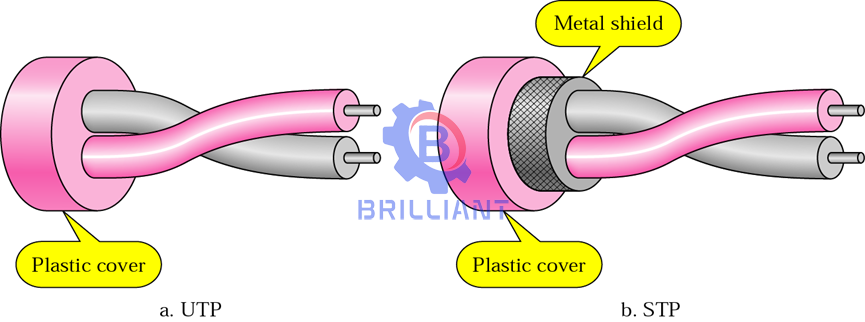

Normally UTP lan cable production need above 5 steps, if need to produce STP lan cable, just need to add a braiding machine to make shielding.

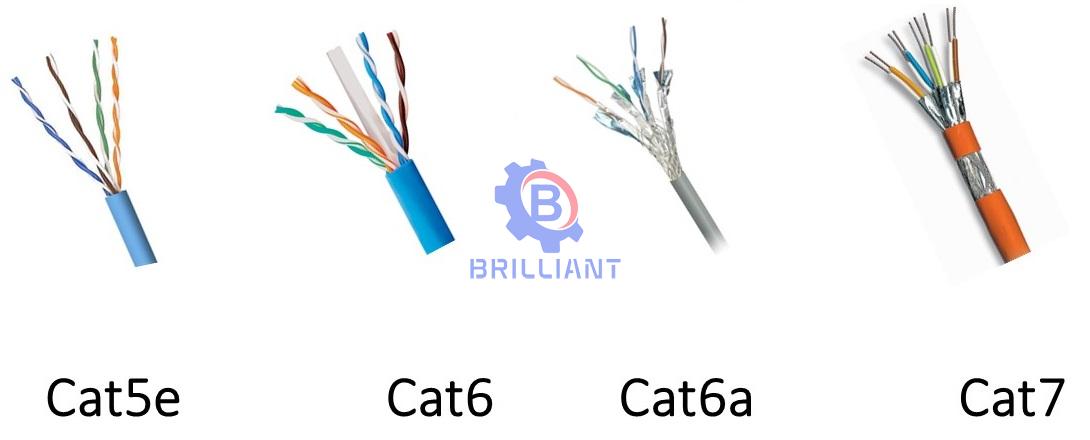

The first step can be changed to be cross-linked wire drawing with extruder to produce CAT6A, CAT7 lan cable which with high standard signal transmission.

All pictures are taken by Zhangjiagang Brilliant Technology Co.,Ltd.

Contact: Lily Peng

Phone: +86 13372130421

Tel: +86-0512-58526133

Email: [email protected]

Add: Tangqiao Town,Zhangjiagang City, Jiangsu Province, China

We chat