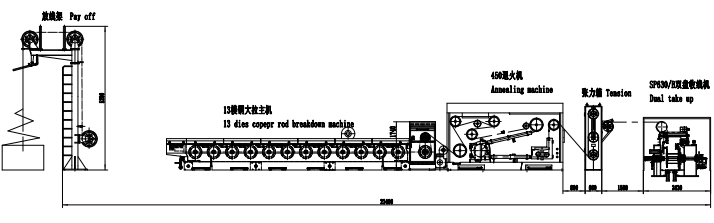

LHT450/13 Copper Rod Breakdown Machine with Annealing

APPLICATION:

This type copper rod breakdown machine with annealing is used to draw and anneal 8mm copper rod to 1.2-4.0mm and take it into spool or coil frame according to the detailed production founction in next step, it apply advanced technology design.

MACHINE DETAILS:

| Item | LHD450/13 | ||

| Inlet Wire Dia.(mm) | Ø 8 | ||

| Outlet Wire Dia.(mm) | Ø 1.2~4.0 | ||

| Max Die No. | 13 | ||

| Max. Line Speed(mm) | 25 | ||

| Main Motor(KW) | 280 | ||

| Drawing Capstan | Coated with tungsten carbide | ||

| Take-up type | Dual-spool take-up, drop coiler, compact coiler | ||

| Lubrication Type | Immersion and spray | ||

FEATURE:

1. The main machine body is an integral casting, with beautiful appearance, advanced structure, low operation noise, high production efficiency and high economic benefit.

2. The diameter of wire drawing drum is Φ 450mm, and the structure of one line inclined arrangement is adopted to avoid the scratch of copper wire and pressing. The machine has high strength and good rigidity. The fixed speed wheel and wire drawing wheel are driven by different motors, and the most advanced structure, and speed synchronous adjustable, can achieve rapid mode change.

3. The main machine is equipped with a special clutch device. When the drawing is larger than the wire diameter of Φ 1.7mm, the clutch device will work automatically, and the last three drums will be separated, so that they will not operate, effectively reducing unnecessary loss.

4. The drawing drum is of immersion cooling type. The drawing die and copper wire can get the best cooling and lubrication.

5. A space is set between the drum cooling lubricating liquid tank and the gearbox to separate. In order to prevent the penetration and mixing of drawing liquid and gearbox oil, multiple seals are adopted in the design and assembly to prevent the penetration.

6. Wire drum, fixed speed wheel and guide wheel are specially treated, with high hardness, good wear resistance and long service life.

Contact: Lily Peng

Phone: +86 13372130421

Tel: +86-0512-58526133

Email: [email protected]

Add: Tangqiao Town,Zhangjiagang City, Jiangsu Province, China

We chat